Induction heating furnaces and equipment

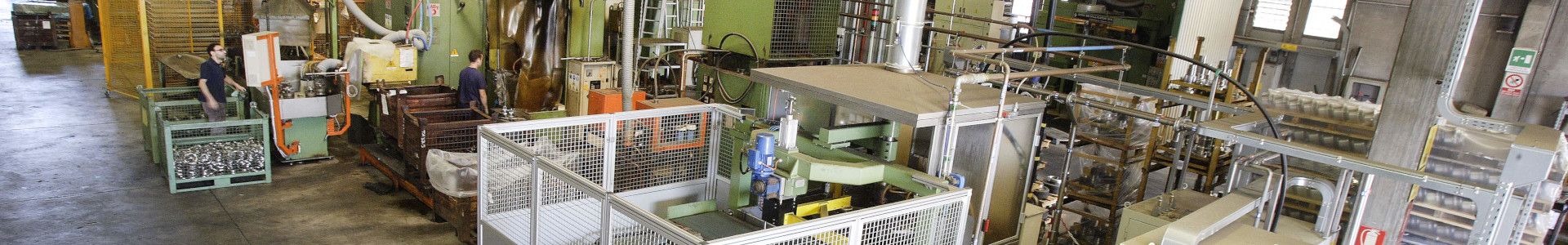

We use furnaces and systems able to harden critical, safety components, large and small series, large and small dimensions.

With over 30 years experience and run by the Biagini family, now in its second generation, Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) provides thermal heating processes and is one of the leaders in the field of induction hardening.

With humility and trusting in research, since 1985, we have invested time and passion to perfect ourselves in the induction hardening sector, a process that aims to improve resistance wear, fatigue and torsion, minimising deformation in treated materials.

First among our objectives stands full customer satisfaction, achieved by ensuring quick and above all quality induction hardening treatment. To do this, we use various plants and heating capacities (high, medium, low frequency), power ranging from 100 kW to 1000 kW and a high level of automation, using a range of equipment with possibilities to handle different geometries and dimensions. All this constantly allows us to work with the system/equipment most suitable for each type of detail to be processed, the result being not only in terms of quality but also the best price. For those customers who need a daily service, where we are part of their production cycle, we accordingly allocate systems, robotic islands and fully automated equipment, working without supervision on three shifts.

We have many cutting-edge and latest generation systems for induction hardening:

- 17 Systems for high, medium and low frequency hardening and power ranging from 100 kW to 1000 kW;

- 23 Items of equipment, positioned in the systems, with process control in order to work the most varied geometries;

- 2 Furnaces for stretching (up to 400 ° C);

- 3 Manual presses for straightening;

- 1 Sandblaster for components up to 1500 mm;

- 1 Automatic boring machine for restoring the deformation of holes.

- 1 Automatic straightening machine, 50 tons. (Galdabini)

Our sophisticated systems combined with inductors developed and manufactured by our engineers and collaborators allow us to create high-performance solutions for induction hardening, without constant adjustment, keeping the metallurgical and dimensional performance constant, not only in the batch under processing but also in subsequent production.

The presence of an in-house laboratory with highly qualified staff and a testing area offers customers not only certified quality on products and processes, but also specialised metallurgical consulting.

Always innovating: this is our creed.

Biagini Tempra Metalli offers a quality service to harden your materials through the induction hardening process; contact us!

INFORMATION

Look at the workings

Gallery

Other services

Metal hardening certifications - induction hardening certified company

Testing after induction hardening treatment

Metallographic laboratory for induction hardening treatment

GALDABINI Automatic straightening machine

Induction heating furnaces and equipment

CERTIFICATIONS

BIAGINI TEMPRA METALLI SRL - Via Porpora, 27-35 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 01594500363

BIAGINI INDUSTRIES SRL - Via Porpora, 31 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 03861000366

Tutti i diritti riservati - sito realizzato da edysma in conformità agli standards di accessibilità ed al Responsive Web Design (RWD)