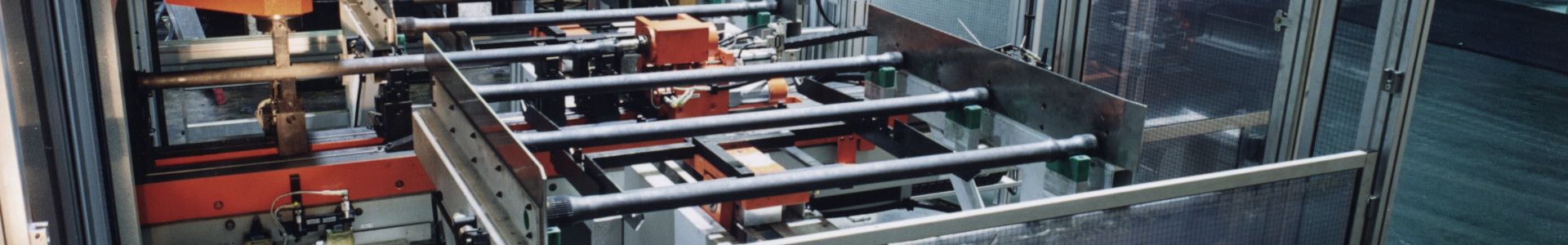

GALDABINI Automatic straightening machine

Thanks to the wide scope of available systems, allowing us to use power from 100 kW to 1000 kW at different frequencies, Biagini Tempra Metalli of Modena is able to perform induction hardening treatment on parts ranging from extremely small to large. From induction hardening heat treatment to the correction of any defects using various latest generation tools, including the Galdabini automatic straightening machine, we at Biagini Tempra Metalli take care of every detail, while also offering a straightening service for treated parts.

Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) is a small business in Emilia with big company mentality. We combine the experience and passion for work of craftsmen, with the confidence in advanced technology of big successful companies, we are equipped with laboratories and highly trained staff, dedicated to the continuous quest for innovation.

Highly qualified personnel and the very latest quality machinery are our strength: two elements that have allowed us to become key players in the induction hardening sector.

Biagini Tempra Metalli, specialising in heat treatment called "induction hardening", runs numerous systems to temper both critical and standard components. Systems for induction hardening at low, medium and high frequency and furnaces for tempering and distension treatments. High power, combined with variable frequencies, enable us to work any piece, shape and size, always perfectly hardening it by induction. Through the versatility of our various machines and the availability of advanced equipment, we are able to cater for all requirements and geometries. Our company in Modena also performs operations on cylindrical straightening.

No stage is overlooked: from the thermal treatment of induction hardening, up to final inspection carried out in our in-house laboratory.

The straightening department allows our company Biagini Industries srl (in wich it became Biagini Tempra Metalli srl) to offer a high quality product, which satisfies geometric/dimensional requirements. Besides several manual straightening machines, we also have a 50 ton Galdabini automatic straightening machine which allows for straightness correction work on cylindrical parts up to 1500 mm in length and 90mm max. in diameter. Thus we guarantee the ability to run checks on 100% of production, optimising the amount of machining allowances and with evident savings in grinding times.

For quality induction hardening treatment, contact us!

INFORMATION

Look at the workings

Gallery

Other services

Metal hardening certifications - induction hardening certified company

Testing after induction hardening treatment

Metallographic laboratory for induction hardening treatment

GALDABINI Automatic straightening machine

Induction heating furnaces and equipment

CERTIFICATIONS

BIAGINI TEMPRA METALLI SRL - Via Porpora, 27-35 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 01594500363

BIAGINI INDUSTRIES SRL - Via Porpora, 31 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 03861000366

Tutti i diritti riservati - sito realizzato da edysma in conformità agli standards di accessibilità ed al Responsive Web Design (RWD)