Induction hardening - induction hardening in Modena

Our company Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) deals with thermal treatment and in particular specialises in the induction hardening sector.

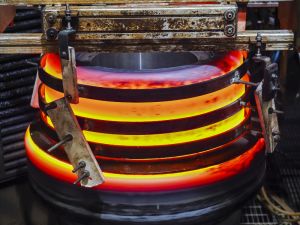

"Induction hardening" is a process which aims to improve resistance to wear, fatigue and torsion in treated materials.

Biagini Tempra Metalli applies this type of surface hardening treatment on IGBT triode or transistor generators (high frequency), with variable frequency (average or low frequency), on components in alloy steel and carbon steel, stainless steel and cast iron parts of mechanical pieces, in order to make pieces more resistant and improve their durability.

In general, the basic components of the induction hardening system are an alternating current generator, an inductor and a "load" (i.e. the material that is to be heated).

The frequency generator produces the magnetic field around the piece to be heated, through the alternating current that is passed through the inductor. The power output of the generator determines the relative speed of heating the piece. When a load is approached, this is traversed by so-called parasitic currents induced by the magnetic field, producing a precise, localised and controllable temperature increase in the material, without any physical contact with the induction coil. The cooling phase follows, which may occur by immersion or spraying.

One advantage that induction hardening has over other types of treatments is a localised treatment. Only the area concerned is treated, which leads to very considerable advantages in both pre/post treatment processing, and considerable economic advantages.

For over 30 years we at Biagini Tempra Metalli have been dealing with heat treatment and, in particular, we specialise in the induction hardening sector: but experience alone is not enough. Love of research and continuous investment in the latest technology is also required. This was the only way we could achieve those goals that today see us as protagonists in the induction hardening sector.

Besides having the very latest generation plant for induction hardening, we can also boast the presence of a laboratory and a testing area. Nothing is left to chance and every stage is followed with great care to ensure the best final result. Our professional technical staff is able to provide accurate, timely and qualified customer assistance: We issue certificates related to the metallurgical analysis of production on your processing work, conducted both before and after the induction hardening treatment, as well as certifications on the hardening depth and structural micrographs.

The hardening of metals by induction is the strong point of Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) of Modena: our perseverance has enabled us to improve day by day, becoming a leader in the field of induction hardening.

The secret of always arriving first: always innovating.

INFORMATION

Look at the workings

CERTIFICATIONS

BIAGINI TEMPRA METALLI SRL - Via Porpora, 27-35 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 01594500363

BIAGINI INDUSTRIES SRL - Via Porpora, 31 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 03861000366

Tutti i diritti riservati - sito realizzato da edysma in conformità agli standards di accessibilità ed al Responsive Web Design (RWD)