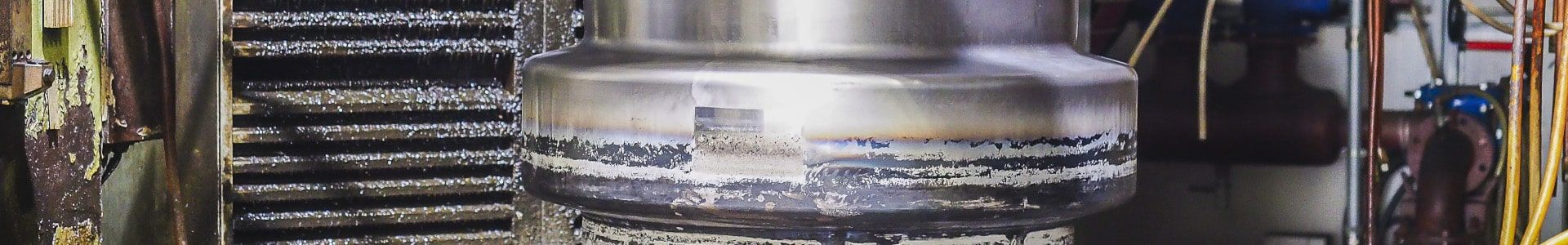

Induction hardening hydraulic parts

Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) is a leading company, equipped with the very latest generation of equipment and technological support of study and research, allowing us to fully exploit the potential of the equipment for induction hardening.

Our goal is to temper increasingly complex and high-performance components or components which so far it has not been possible to harden. We are not only content with the results achieved, but always tend to improve and go beyond our goals. We work to customers’ designs and produce as required, with regard to the induction hardening treatment; we are also able to collaborate with engineering to propose solutions until today not requested, simply because they are considered unfeasible.

The extensive range of equipment and the technical quality achieved by our company provide the ability to operate on a variety of geometries and sizes, and to carry out the induction hardening of hydraulic parts, internal and external profiles and various simple or complex geometries.

Thanks to our equipment, which combines varying frequencies with high power, we can process an extremely wide range of parts and forms with induction hardening: the fact of having different systems allows us to meet any need and geometry.

For example we can use induction hardening for hydraulic parts to handle internal and/or external shapes, with millimetre dimensions, as well as parts for the automotive and motorcycle industry, undercarriage components for earthmoving equipment and industrial vehicles; again we can process oil seals, scraper rings of any size, linear bars up to 16 meters long, gears, crown gears, axles and wheels.

By "hydraulic parts" we mean those elements inserted inside a hydraulic circuit and necessary for it to work properly. Their function is of paramount importance and this is why the induction hardening of hydraulic parts is always carried out under optimum conditions.

Decades of experience in the industry, coupled with the continuous search for new technologies and innovative methods to be applied in the treatment of induction hardening, have enabled us to achieve optimum results as regards quality and speed of delivery, positioning us as leaders for induction hardening treatment contract work.

Always innovating: this is our creed and our strong point. For the induction hardening of hydraulic parts, mechanical parts, complex profiles and more, contact us! We will be able to recommend the best solution for your needs!

INFORMATION

Look at the workings

Gallery

Other services

CERTIFICATIONS

BIAGINI TEMPRA METALLI SRL - Via Porpora, 27-35 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 01594500363

BIAGINI INDUSTRIES SRL - Via Porpora, 31 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 03861000366

Tutti i diritti riservati - sito realizzato da edysma in conformità agli standards di accessibilità ed al Responsive Web Design (RWD)