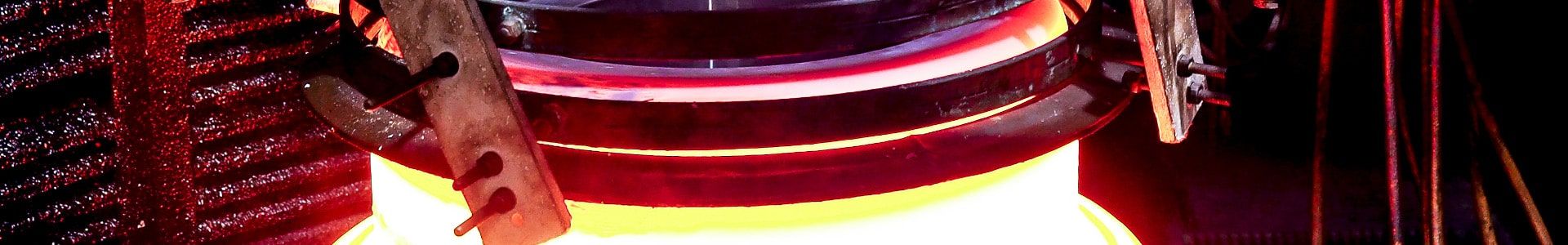

Induction hardening of internal and external profiles

Biagini Industries srl (in wich it evolved Biagini Tempra Metalli srl) is able to temper any steel and cast iron component with internal/external profiles using the induction hardening process: We have been working in the field of heat treatment since 1985 and we specialise in particular in the field of induction hardening.

The long-term experience of our engineers and managers, coupled with constant research in new technology and advanced equipment, has led us to become one of the major leaders in the field of induction hardening in the area of Modena, Reggio Emilia, Parma and Bologna, and more generally in northern Italy.

With our equipment, combined with generators with variable power and frequencies, we can apply induction hardening treatment to any piece and shape. The fact of having different machines, fully automated and fully reliable, allows us to meet any need, working countless products, different in size and geometry. For example, we can apply induction hardening on both internal and external profiles, with straight or curved lines, simple or complex.

Why ask us for processing using induction hardening for internal/external profiles, with curved lines, etc.?

Because Biagini Tempra Metalli means experience and innovation at the same time: current equipment includes 17 systems for induction hardening with high, medium and low frequency and variable power from 100 kW to 1000 kW. The frequency range allows us to achieve hardening depths from 0.5 mm to 30 mm. The power instead gives us the possibility to range from small to large size details.

It is understandable, therefore, how the sum of the high technical/technological quality which distinguishes us for years in the industry, allows us to operate on a variety of shapes and sizes, carrying out the process of induction hardening on internal/external profiles with minimal deformation but above all keeping these constant and thus manageable.

Each batch is accompanied by a quality certificate which includes the various tests performed on the treated parts and the number of pieces made, with the traceability references provided by the customer.

Precisely in order to ensure a better quality of services offered, the company Biagini Industries srl (in in wich it became Biagini Tempra Metalli srl) of Modena has an in-house metallurgical laboratory which allows analysis to be carried out on samples treated in the furnaces department. In this way we can quickly verify the effectiveness of the induction hardening process and compliance with the specifications required by customers.

Our technical laboratory experts will be able to recommend the most suitable conditions to harden your products by the method of induction hardening. To evaluate what would be the best solution, please contact us!

INFORMATION

Look at the workings

Gallery

Other services

CERTIFICATIONS

BIAGINI TEMPRA METALLI SRL - Via Porpora, 27-35 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 01594500363

BIAGINI INDUSTRIES SRL - Via Porpora, 31 41122 Modena (Italy) - Tel: 059.281205 - P.IVA: 03861000366

Tutti i diritti riservati - sito realizzato da edysma in conformità agli standards di accessibilità ed al Responsive Web Design (RWD)